-

13# Yongjia Road,Economical and Technology Development Zone ,Shuyang,Suqian,Jiangsu,China

13# Yongjia Road,Economical and Technology Development Zone ,Shuyang,Suqian,Jiangsu,China

13# Yongjia Road,Economical and Technology Development Zone ,Shuyang,Suqian,Jiangsu,China

13# Yongjia Road,Economical and Technology Development Zone ,Shuyang,Suqian,Jiangsu,China

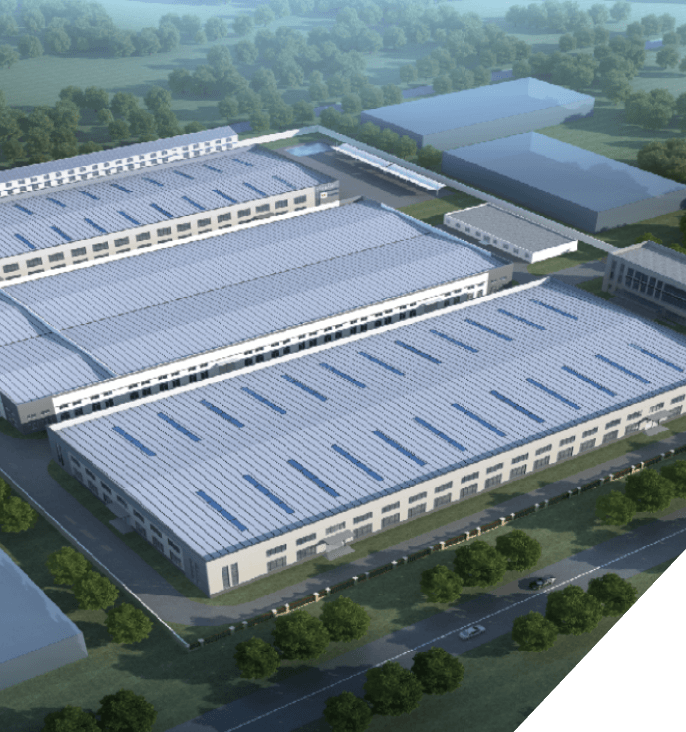

With two subsidiaries Nantong Carto Auto Parts Co., LTD and Jiangsu Rainbow Auto Parts Co., LTD.) was established in 2007, with nearly 20 years experience in the automotive industry. It’s headquarter locate in Shuyang Economic Development Zone, Suqian City, Jiangsu Province, the factory covers an area of 60 mu, with a construction area of 37500 square meters, and currently employs about 600 people. The main products are automotive cooling system pipeline, thermal management system pipeline, intake and exhaust system pipeline, air conditioning system pipeline assembly, silicone tubes for new energy area, rubber molding products, rubber extruding seals and belts.

Our company has product development and design capabilities, hose performance experiment, product testing, quality management and a series of control procedures, with TS16949 and ISO9000 system certification ,we entered the mainstream automotive OEM supporting system in domestic and abroad, products are widely used in automobile, construction machinery, agricultural machinery, hydrogen energy vehicles and other industrial fields.

The revenue of 2023 has been reached 250 million USD,and keep 10-20% increasing in the past 5 years.

"pioneering and innovation, quality win, integrity-based, the pursuit of excellence" as our eternal purpose; Always adhere to the concept of win-win with customers, and look forward to working with you to create our tomorrow!

Auto OEM manufacturers and aftermarket parts wholesalers are our main service customers. For car manufacturers, we assist in refining design plans, validating design outcomes, selecting the most suitable materials and processes to meet the customer's usage and budget goals.

For the aftermarket sector, we typically match appropriate products directly based on samples or drawings provided by customers and cost requirements.

There is a variety of construction equipment used in the industry. Here are some of the most common types: Backhoe,Graders,Excavators,Bulldozers,Pile driving machine,Wheel loader,Trenchers, Compactors

Each of these machines uses custom molded rubber parts. From engine mounts to suspension systems, rubber parts help maintain efficiency and improve uptime.

Farming machinery typically fueled by diesel or gasoline, these power plants use an engine-driven pump to circulate coolant through passages in the engine block and cylinder heads. Engine cooling tubes and engine cooling hoses are important parts of this system, and are made of rubber and plastic materials that resist water, antifreeze, and corrosion inhibitors. These coolant tubes and hoses must also resist extreme service temperatures.

The company first passed the TS169494 quality system certification in 2018, and renewed the certificate through a required re-audit upon expiration.and get ISO9001 and 14001 certified in2023 too.And also we have over 10 patents in new engery fluid design and application.

The raw materials and finished products are fully compliant with the design requirements of our customers, and we can provide official testing reports from third-party laboratories as requested by customers.

We strictly follow the quality management requirements of TS16949, monitoring and adjusting every aspect of the production process to ensure product quality meets the standards. This includes raw material procurement, production manufacturing, product inspection, and other aspects.

We utilize ERP systems, barcode technology, RFID technology, etc. to record and trace every aspect of the production process, including production time, personnel, equipment, and other information.

Unvulcanized rubberMooney viscosity/Prevulcanization characteristics/ Hardness/Tensile Properties/Tear strength。

Vulcanized or thermoplasticrubber Hardness/ Tensile Properties/Tear strength/Liquids resistance/ Heat resistance/Compression set /Ozone resistance/ Density/Corrosion of metals/ Low temperature brittleness/ Surface cracking/Transmission of liquids, Hydrostatic testing/low temperature flexibility/ Bending tests.

Testing equipmentsElectronic Tension Tester/Curometer/Infrared Spectrometer Mooney Viscosity Tester/Micro-durometer/Ozone Tester Rated burst laboratory table/Flexibility Tester/Cleanliness and Particle analysis system/Automotive hose multi-purpose tester

They have amazing staff and customer service. They were very responsive and were incredibly kind and patient with any questions/concerns I had.

It was amazing to work with. I worked with them on several products and I honestly can't imagine working with anyone else.

I've ordered from them a couple of times and have not been disappointed! They reply quickly to my messages and always update me.

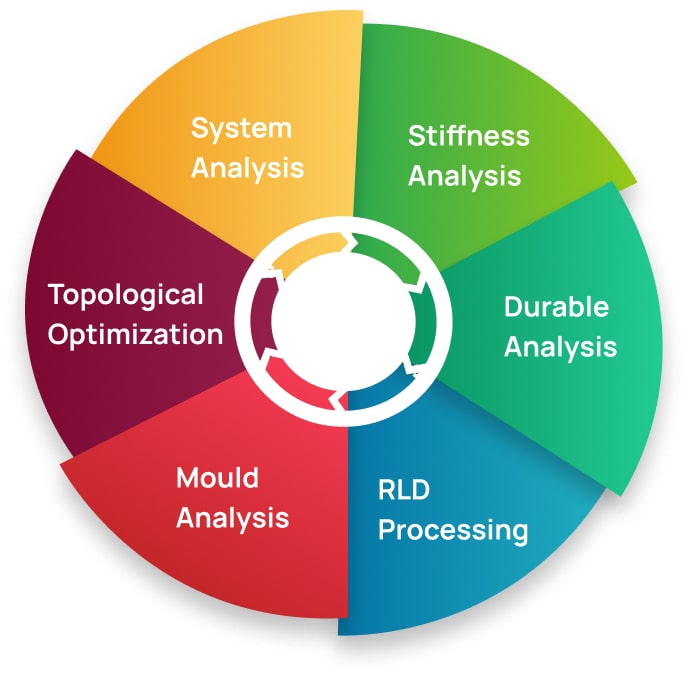

Our company currently has 40 technical personnel with the capability to develop rubber hoses and other rubber-plastic parts. We possess over 10 authorized patents in materials, tooling, equipment, and processes. All personnel involved in technical development are proficient in 3D software (CREO, UG, CATIA) as well as 2D software (CAD).

Our team can assist OEM customers in system module design and conduct practical verification to ensure the feasibility and implementation of the design scheme, continuously optimizing and adjusting the design scheme in practice to achieve the best results. Our commitment to innovation is underscored by the several patents we have secured, reflecting our expertise and dedication to advancing technology.